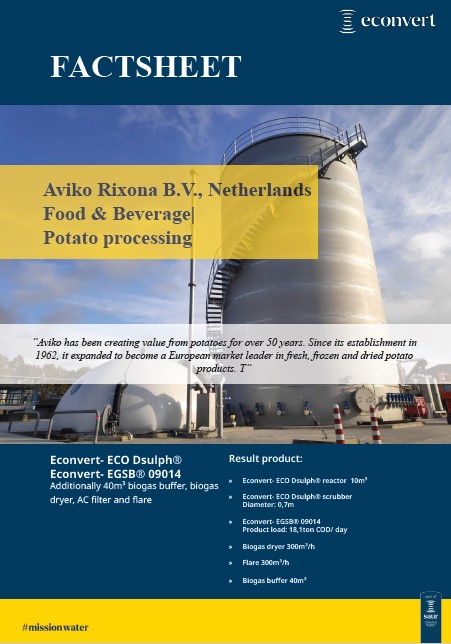

Aviko Rixona is part of Royal Cosun, which is the market leader in the production of fresh, frozen and dried potatoes. We spoke with Henri van Laarhoven, project office manager at Aviko Rixona. He is happy to tell us more about how the good cooperation with Econvert when purchasing an Econvert-IR.

'Why were you looking for an industrial water treatment plant?'

‘The Aviko Rixona factory was expanded a few years ago. With an eye to the future, we weighed up various options to also increase our purification capacity.

We already had an aerobic water treatment plant. By supplementing this with an anaerobic water purification with biogas treatment, we have greatly expanded our capacity.’

What solution did Econvert offer you?

‘An Econvert-EGSB® for the purification of the water and a Dsulph® for the treatment of the biogas. We reuse the biogas again in our steam boiler in the factory, which means we save on purchasing natural gas, the aerobic purification is biologically relieved and the electricity bill is reduced.

We relieve the aerobic installation and also purify the water with an anaerobic installation. By doing this we reduce our CO2 emissions. This is because the biogas is reused in the factory and less biomass is being produced in the aerobic water purification. With less biomass having to be removed from the aerobic installation this also reduces the needs for road transportation and its associated costs.'

We relieve the aerobic installation and also purify the water with an anaerobic installation. By doing this we reduce our CO2 emissions. This is because the biogas is reused in the factory and less biomass is being produced in the aerobic water purification. With less biomass having to be removed from the aerobic installation this also reduces the needs for road transportation and its associated costs.'

‘Econvert knew exactly what we needed and also advised us on how the installation fit into the current process..’

'Why did you choose Econvert?'

'We invited various companies to make a proposal. After a number of rounds there were still two companies left, including Econvert. Their expertise and solution-oriented approach appealed to us. They knew exactly what we needed and also advised us on how the installation could fit into the current process'.'What was the result of the project?'

'We are a satisfied customer. Even after the installation has been completed, Econvert will continue to monitor the performance of the installation. They have a high level of service and are always available should there be any problems. Econvert is a reliable partner that we enjoy working with.’